I am need of some rep. So I thought I would post a technical thread to help out people. The brake/rotor job is basically the same from vehicle to vehicle. Please use this as a guide, but not an absolute. It's just better than the Haynes manual and has pretty pictures

The car used was a 2000 Civic Si. Most cars, especially Hondas, use similar setups. Consult your specific model for correct torque settings.

Things needed:

10 mm, 12 mm, 14 mm, 17 mm wrenches and socket wrenches.

Foot-Pound torque wrench

Jack and stands

Pads and Rotors

Brake clean

Shop towels or low lint paper towels

Water

Patience

Optional, but highly recommended:

Impact gun

Impact driver

Let’s start.

Get your stands and jack situated correctly to raise the vehicle. You can either work the front and the rear separately, or you can work each side separately.

Raise the vehicle and support the car from the correct positions. Be sure to add something to both the front and rear tires on the opposite side to keep the car extra stable. You do not want the car on top of you.

I have an impact gun. Dewalt 345 ft-lbs of sheer madness to get those pesky lug nuts off. A breaker bar or something should be sufficient to break them loose, but since they should be torqued to 80 ft-lbs, you shouldn’t need a breaker bar too much.

Now that you have your wheel off, first take the brake line support bolts off. They should be a 10 mm. (8.7 ft-lbs)

If possible I always try and keep the bolts/nuts in place after I remove the item so I don’t have extra parts hanging around after a job. Put those two bolts back in position.

Take off the lower caliper bolt (24 ft-lbs). This provides access to the pads.

Flip the caliper up and take off the old pads. If you are just inspecting the pads then note that they should have 9.5 – 10.5 mm of pad thickness. The minimum limit is 1.6 mm.

Mine were very low and since I was about to track my car, I knew I should replace them.

:note: the wear indicator sticking down, this should be installed on the front pads on the top side facing in toward the motor.

Take the caliper mounting bolts off. These are a bit tougher to get since they are (80 ft-lbs)

Support the caliper with wire to prevent damage to your brake lines.

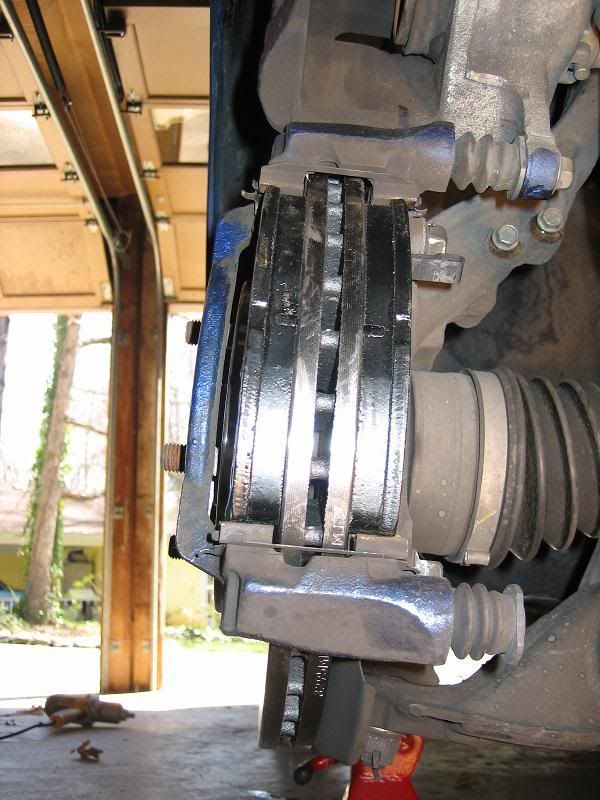

A pic of my new pads on the left (Hawk HP+) and OEM on the right

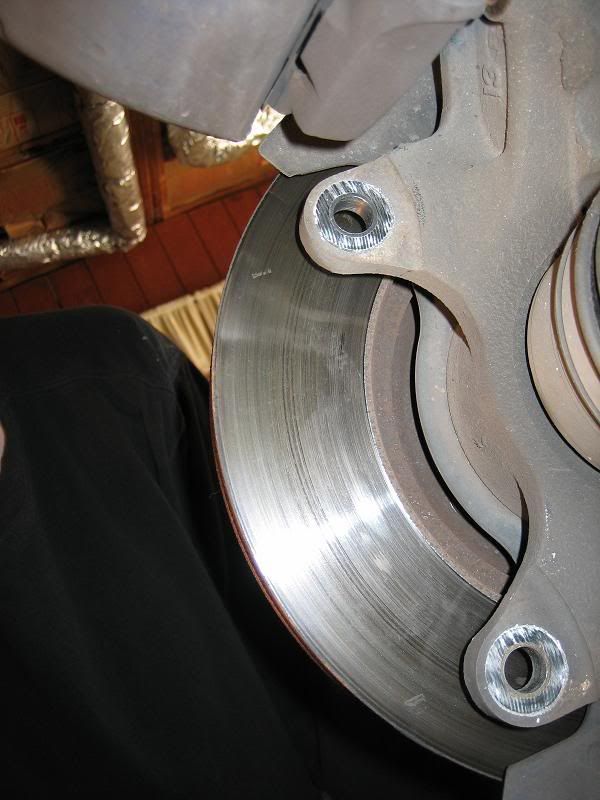

Now you are ready to take the rotor off. Here is where that impact driver comes to play. There are two retaining screw that hold the rotor to the hub. These things are heated to very high temperature when you brake and have a tendancy to rust freeze in place if anti-sieze was not used. I think the last person who did this job used loctite. Get an impact driver and a hammer. This will release those screws easily.

I wanted to salvage my rotors because I measured them and they were well within spec. The Helms stated that 8x1.25mm bolt could be screwed into the other 2 holes to push the rotor away from the hub. I found a bolt from the upper support bolt holding in my power steering. So I used it.

:note: don’t screw too much on each bolt without turning the other, or else damage to the rotor can happen. Twist each bolt about a turn then turn the other. The rotor will come off shortly.

Put the new rotor on

I put those damn screws back in just to hold the rotor on. Once I completed the job for each pad/rotor I took them off.

Put the caliper back on so the new pads can be placed in the caliper. Be sure to use pad grease. DO NOT PUT PAD GREASE ON THE ROTORS OR PADS

Slowly roll the caliper over the pads. You may need to push the piston back in order to place the caliper over the new pads. I pushed the piston in with a dowel and opened the bake bleed screw (6.5 ft-lbs) Be sure to bleed the brakes after the job is done to ensure no air is trapped.

Installed! Now use that brake cleans and sprtiz down the pads and rotors to get rid of fingerprints, oil, dirt, anything to contaminate the brakes.

On to the rear!

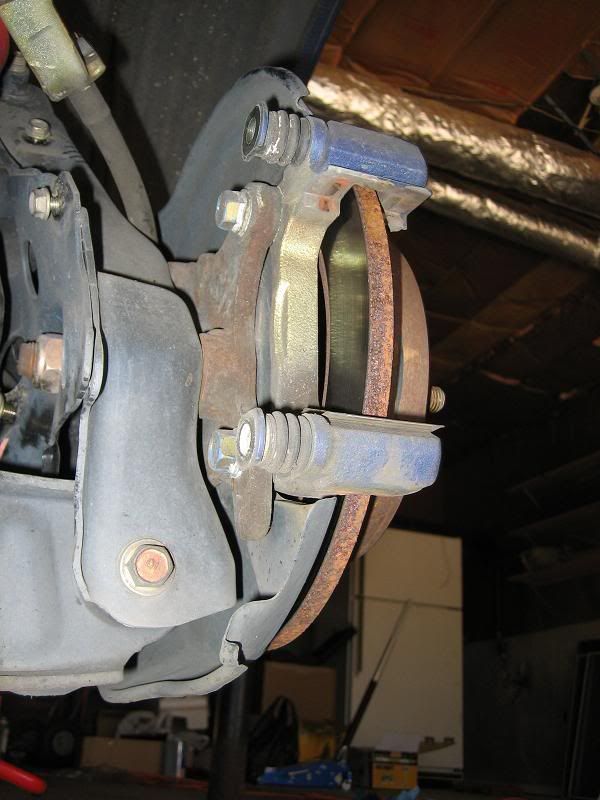

Take off the caliper shield (on floor 7 ft-lbs) and take brake hose mounting bolts (16 ft-lbs)

Then take the caliper bolts off (17 ft-lbs) and support the caliper.

Take the caliper bracket off. These bolts are ( 28 ft-lbs)

Again…those damn screws.

I didn’t have wood or a plastic mallet and was replacing the rotor anyway. So I took a hammer to the backside and the rotor flew off. Oh well…New one on there now.

The rear caliper piston is much easier to get in. Simply take a pair of needle nose pliers and screw the piston in clockwise.

Line up the notch of the inside rear pads to fit inside the “cross” in the piston.

Torque everything to spec

Beer time!

I broke in my pads by first driving around my neighborhood at 30 mph and slamming the brakes to 20 mph. Do not drag the brakes at this time. Then I went out to the major street and ripped it. 80 mph down to 60 mph a few times and then back to the house to let them cool off. Be sure to keep the car level and do not have the emergency brake on at all. Leave them alone for an hour or so. They should be broken in. Mine officially set in a few laps at Talledega Gran Prix. I never knew I could make brakes smoke like crazy.

Reply With Quote

Reply With Quote