http://www.youtube.com/watch?v=h6RZKqzAaHY

Shows in great detail how the carbon fiber is made, how the car is constucted, 7 post rig, and how the metals are made.

http://www.youtube.com/watch?v=h6RZKqzAaHY

Shows in great detail how the carbon fiber is made, how the car is constucted, 7 post rig, and how the metals are made.

Very, very interesting... Great find, EJ. +30

DAAAMMMMMNNNNNN! I knew a lot of things went into making these cars, but that machine that used lasers and epoxy resin to make 3d parts was amazing. I've never seen anything like that before. Bringing the car back to the factory after every race to fix a paint chip in the booth is a little too much. Not to mention that factory was spotless even with all that white stuff all over the place.

nice vid.

I wouldnt say great detail though.

rapid prototyping is probably the coolest technology out right now. Comparatively speaking, its not every expensive either.

every F1 team, some manufacturer, and even smaller teams have white factories. That way you know if there is a tiny spec of dust that could fall into an engine, or carbon work, or gearbox, or even paint. everything has to be perfectly clean all the time. any small contamination could prove to be a costly mistake.

49 States, 4 corners and the Arctic Circle. solo Supersport Ride for Alzheimers.

www.motovagabond2011.blogspot.com

http://www.advrider.com/forums/showthread.php?t=696125

www.alzfdn.org/

www.Projectlifesavers.org

www.DIDChain.com

www.ZeroGravityRacing.com

My Facebook Page

http://www.facebook.com/profile.php?id=503472773

I'm fully aware of that. I know there is one motorcycle company that requires everyone to wear white uniforms because of that.Originally Posted by dazn

^^ Honda has done this since the beginning. We had something similar to the epoxy in a drafting class I took, it wasnt near as high tech but it did the same thing. Ours used glue and some form of powder, it certainly wasnt strong enough for wind tunnel testing but it would sit on a shelf nicely.

FWIW, generaly rapid prototyping is pretty expensive unless you own the machine. Even then the material is very expensive, especially for parts that actually need to go on the race car. The cheaper materials are closer to a waxy resin that melts and loses form with heat, vibration, and pressure. Rapid prototype parts in general are used to test a design, quickly, easily, and cheaper than it would be to make a part from Carbon or metal.

To make a wind tunnel model from molds, carbon fiber, fabricated parts, and billet parts will take alot more time and money than it will to create it with a rapid prototype. Not to mention if the design needs to be changed all you have to do is manipulate the cad model. Falcon Car's (formely run by Ken Anderson) made an entire full scale car with a rapid prototype by designing and making each piece. It was pretty neat and a much cheaper way to create the prototype car.

More amazing than all that technology is the fact that those shitty tasting drinks are the $$ force behind all this money...

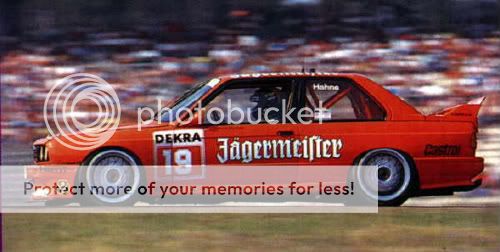

That shitty tasting drink becomes an amazing tasting drink when combined with the wonderfully tasting Jagermeister. Just sayin'.Originally Posted by Atlblkz06

NIKON Squad member | Nikon D200 | Sigma 24-70 f/2.8 | Sigma 70-200 f/2.8

Only thing going through my head reading that.Originally Posted by DJ Maestro

+

Originally Posted by Jenson

Thats what I mean by comparatively cheap. obviously the initial investment in the machine is very expensive, but in the long run compared to making parts and molds the old fashioned style, you can save a lot of materials and man hours.

49 States, 4 corners and the Arctic Circle. solo Supersport Ride for Alzheimers.

www.motovagabond2011.blogspot.com

http://www.advrider.com/forums/showthread.php?t=696125

www.alzfdn.org/

www.Projectlifesavers.org

www.DIDChain.com

www.ZeroGravityRacing.com

My Facebook Page

http://www.facebook.com/profile.php?id=503472773